To help illustrate how the Fourth Industrial Revolution (Industry 4.0) and the Industrial Internet of Things (IIoT) are transforming industry, let’s look at the effects already being felt in flexography—the printing process which can be used to print on plastic, metallic films, cellophane, and paper.

The foundation of Industry 4.0 and IIoT is digitalization—the process of converting information into bits for use by intelligent systems. Digitalized systems enable greater uptime through predictive analytics, faster changeover through automated motion, superior quality through precision and repeatability, and greater sustainability through lowering waste and energy consumption.

Digitalization is also changing the relationships between suppliers and customers by drawing printing operations personnel, IT departments, equipment OEMs, and their tier-one suppliers into new and highly effective proactive/virtual teams. The goal of these teams is to maximize overall equipment effectiveness (OEE) and grow their print operation’s business through assured customer satisfaction.

Even with all the focus today on Industry 4.0 and IIoT, it’s important to realize that technology is not where the story of digitalization for improved profitability begins. Instead, it starts with social change. One of the most notable of these changes is the critical shortage of skilled press technicians, as fewer people today choose manufacturing careers.

Furthermore, society’s thirst for new products, as well as custom products, has led to the proliferation of stock keeping units (SKUs), making it difficult to profitably run printing presses because its takes time to changeover the press and adjust it. At the same time, retailers and the public expect industry to strive to reduce waste and lower energy usage during production.

The social trends of fewer skilled workers, SKU proliferation, shorter product lifecycles, and greater sustainability were factored into the development of Industry 4.0 concepts. Industry 4.0 envisions modular and reconfigurable manufacturing systems that lower capital costs and shorten time to market for new equipment. Industry 4.0 concepts anticipate the merger of automation and big data in manufacturing, IIoT cloud-based systems, cyber-physical systems that change functionality based on downloadable algorithms, and artificial intelligence (AI).

Industry 4.0 is not a destination, but rather a direction that technologists and motion system providers apply to their product development roadmaps. Leading flexographic press OEMs also include key Industry 4.0 concepts into their product development plans.

Industry 4.0 and IIoT innovations are not simply the province of futurists. Developments are available now that involve hardware and software combined with AI to automate complex printing adjustments. For example, a new AI solution can automatically stabilize the print process by suppressing the disturbance associated with the hard edge. This AI-based system largely removes the impact of bounce in flexographic printing for greater quality, less waste, and faster changeover. Without digitalization this solution could never have happened.

The following are additional examples of intelligence, automation, and other design changes being added to flexographic presses today by leading OEMs to ensure that presses run more automatically with faster changeover and more sustainable operations:

- Sleeved plate and anilox mandrels for faster print job changeover;

- Automatic viscosity control systems for maintaining consistent print quality;

- Automatic print impression setting for reducing waste;

- Automatic registration setting for reducing waste;

- Highly effective drying systems that promote higher production speeds;

- Automatic splice/transfer winders for higher up-time;

- Automatic print deck wash-up systems for faster print job changeover;

- Inline print inspection systems for real-time print quality monitoring;

- Web thread-up system for higher up-time; and

- Automatic impression cylinder wash-up system that offers efficient maintenance of the cylinder surface.

Enabling technologies

Following are some of the leading hardware and software systems available today that take machines to the next level of productivity. Expect to see increasing use of these technologies as new machines are introduced.

- Intelligence down to the sensor level is essential for predictive analytics. The ability to predict faults before they happen and improve OEE. One of the most important recent developments has been the IO-Link open standard for smart sensors. IO-Link-based sensors cost about the same as other sensors but have the added value of faster commissioning, greater data acquisition, and data integration with the cloud through IIoT. Along with IO-Link, a range of intelligent sensor technologies are making an exceptional contribution to improved operations.

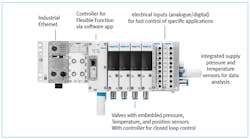

- New Remote I/O systems are a vital and cost-effective means of driving intelligence deeper into the machine, while making installation faster and easier. Remote I/O systems boost system performance improvements through faster overall automated response. Smart energy conservation hardware and software monitor compressed air consumption and provide information and control that minimize energy usage.

- Cyber-physical motion. Systems that change functionality via downloadable apps offer rapid change in functionality, flexibility, and the cost advantages of lowering the number of components requiring support. For example, a single cyber-physical pneumatic valve pack can potentially replace dozens of different components.

- AI-based systems make complex machine adjustments automatically, quickly, and precisely.

- Ethernet gateways for secure cloud-based analytics are becoming more ingrained in control architectures.

Operation of complex machines benefits from virtual internal and external teams available 24/7 to accurately diagnose and rectify issues before OEE is affected. These teams will be staffed by internal maintenance personnel, the OEM, and, as required, key component suppliers. Team members will collaborate in real-time via emerging web-based applications and mobile devices. Internal IT departments will create connectivity solutions that facilitate access yet maintain overall enterprise security.

To combat unplanned downtime, press OEMs and printing operations’ maintenance personnel will collaborate in the use of cloud-based predictive analytic tools to proactively identify components in imminent danger of failing. For example, it is now possible for a press OEM to utilize a dashboard to predict a pump or drive failure several weeks or even months ahead of an actual incident. In this scenario, the OEM alerts maintenance personnel to the problem, and the internal maintenance team replaces the failing component before it causes an unexpected shutdown.

All of the technologies mentioned in this article are available now and are becoming widely available. Leading OEMs are providing presses that address the issues of cultural change in more automated processes, faster changeover, and improved sustainability.