Sustainability has been a major driver of business and technology decisions for the better part of the past two decades. For manufacturers, the growing importance of sustainability is reflected in the capabilities of automation technologies—from increasingly efficient motors and drives to energy management software.

“Sustainability has to be an integral part of the [design and production] process,” said Tony Hemmelgarn, president and CEO of Siemens Digital Industries Software, at Siemens Realize Live 2023 event. “It can't be this bolt on that comes later. And it’s not just [related to] product design. It's supply chain interaction, it’s service, it’s reuse, it’s factory automation, it’s manufacturing execution and manufacturing, engineering—all of these pieces have to be considered.”

Hemmelgarn noted that the pervasive importance of sustainability to industry is driving much of Siemens investment in delivering a comprehensive digital twin. “Sustainability has gone from being a political statement to a business decision to drive greater efficiencies,” he said.

What’s changed?

In the early 2000s, one of the bigger issues around industrial sustainability involved helping manufacturers realize that the concept was not just about “going green” but in recognizing the long-term impact on cost savings despite the upfront costs.

Most industrial companies are trying to do many different things to achieve cost savings and operational improvements, said Devola. Sustainability is gaining ground because it tends to impact “multiple important incomes or KPIs (key performance indicators) at the same time,” she said.

She added that, in addition to consumer behaviors around sustainability, manufacturers are also being driven by “regulatory landscapes and incentives. You see a series of carrots and sticks—and the EU is very stick-driven. So, if you want to trade in Europe, there are specific requirements you have to meet. And in the U.S., we've got the inflation Reduction Act that’s targeting billions of dollars toward sustainability and acting as a carrot to lead people to think about how they can take advantage of these financial incentives.”

New tech developments

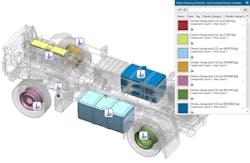

In keeping with Siemens’ focus on helping make sustainability part of a company’s business strategy, the company has added Sustainability Impact Analysiscapability to its NX CAD/CAM software. NX is part of Siemens’ Xcelerator portfolio. According to Siemens, this software “puts environmental impact assessment front and center of a product’s development workflow. This is the first time that a product engineering solution has delivered EN15804-based sustainability metrics based on accurate 3D design data combined with an artificial intelligence driven material recommendation engine. It allows organizations to calculate, evaluate and optimize the impact of design decisions and material selection based on a diverse and comprehensive set of 30+ environmental impacts combined with a complete 3D design integrated sustainability reporting.” Siemens says the “integrated nature of the Siemens Xcelerator portfolio means that the same data is available for reuse downstream and when connected to the wider enterprise. Environmental targets and requirements for design can then be driven from requirements captured in Siemens’ Teamcenter software for product lifecycle management and used for validation against requirements and environmental credits.

To address this issue, Siemens offers SiGreen, an emissions management tool that takes the carbon footprint data from your production operations and connects it to your supply chain data and “aggregates the data on a per SKU per product basis,” Devola explained. With these insights, you can start to look at the carbon footprint of a product. “And as you make changes to the supply chain or manufacturing methods, you can see the impacts,” she said.

This connection of manufacturing and supply chain data is critical, said Gunter Beitinger, senior vice president of manufacturing at Siemens, as “up to 90% of CO2 emissions are not generated within production processes but rather along the supply chain.”