Bimbo Bakeries USA (BBU) is considered the largest bakery company in the United States, producing brands such as Sara Lee, Entenmann’s and Thomas’. The company operates 59 bakeries, employs more than 20,000 associates and distributes products through 11,000 routes that service the majority of store outlets offering baked goods in the U.S.

The perishable nature of baked goods demands rigorous stock management for the freshness that shoppers expect. As a result, manufacturers like BBU must walk a fine line between waste due to overstocks and lost sales from out-of-stocks.

To achieve the organizational transformation needed for these improvements, Morgan Smith, BBU’s vice president of direct store delivery (DSD) center of excellence, first sought to better understand the challenges of bakers on the production line as well as front-line workers such as DSD drivers. What he learned led to a new view of the production-to-consumer “chain of command” that inverted the order of importance and made everyday consumers the most important stakeholders, followed closely by the company’s front-line teams that directly serve them.

To support this new customer-driven orientation, BBU’s front-line workers needed purpose-built, data-driven technologies to help them do their jobs better and pass real-world insights to senior management.

Based on worker feedback on how an ideal solution would make their jobs easier, BBU introduced a new artificial intelligence (AI) powered approach—named Ion—which centers on the company’s proprietary demand intelligence platform to serve as the frontline workers’ assistant.

Predictive ordering benefits

To improve forecasting, antuit.ai applied an AI workflow to analyze demand and detect data outliers. BBU wanted to identify demand drivers and their impact, test for the hierarchy level that would drive the highest forecast accuracy and leverage machine learning to break down the forecast to the appropriate consumption level for ordering purposes.

Antuit.ai’s forecasting methodology considered more inputs—many captured directly from retailers and route drivers—going well beyond historically-driven base and promotion demand to include real- or near-real-time inputs, such as weather, local events, store stocking constraints and point of sale data. The AI-powered demand forecasting and predictive ordering technology behind Ion helped right-size production and localize delivery on a SKU/store/week level by factoring in this more granular data.

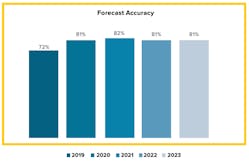

Based on mean average percentage error data tracking for six-week intervals occurring at the same point in time each year, over the past five years (which included the unexpected variations caused by the COVID-19 pandemic) BBU was able to achieve and maintain a greater than 80% forecast accuracy despite the extraordinary events impacting its consumers’ lives during this timeframe.